Kotły centralnego ogrzewania

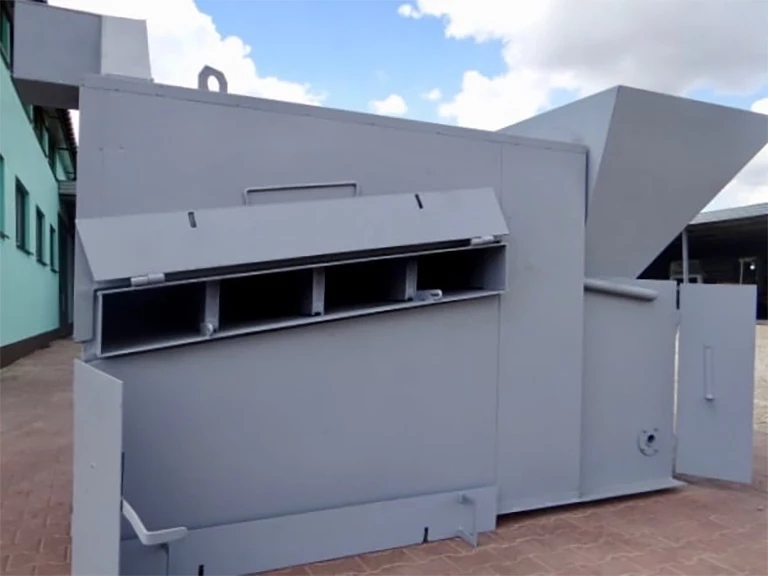

Zajmujemy się produkcją kotłów centralnego ogrzewania. Możemy pochwalić się ponad 30-letnim doświadczeniem w branży. Jednym z naszych najważniejszych profilów działalności jest wykonywanie kotłów miałowych o dużej i średniej mocy. Zamawiając u nas kotły, Klienci zyskują możliwość indywidualnego zaprojektowania urządzenia, które będzie mogło spełnić specyficzne wymogi inwestora. W naszej ofercie znajdą Państwo również piece uniwersalne – opalane mieszanką węglowo-miałową, węglem, drzewem i biomasą.

Zajmujemy się produkcją kotłów centralnego ogrzewania. Możemy pochwalić się ponad 30-letnim doświadczeniem w branży. Jednym z naszych najważniejszych profilów działalności jest wykonywanie kotłów miałowych o dużej i średniej mocy. Zamawiając u nas kotły, Klienci zyskują możliwość indywidualnego zaprojektowania urządzenia, które będzie mogło spełnić specyficzne wymogi inwestora. W naszej ofercie znajdą Państwo również piece uniwersalne – opalane mieszanką węglowo-miałową, węglem, drzewem i biomasą.

Dlaczego warto wybrać naszą ofertę?

Wszystkie nasze produkty charakteryzują się doskonałą sprawnością energetyczną, dzięki czemu ich użytkowanie jest zarówno wygodne, jak i opłacalne pod względem ekologicznym i ekonomicznym. Produkowane przez nas kotły o średniej mocy wyróżniają się rewelacyjną trwałością i wieloletnią żywotnością. W naszej codziennej pracy korzystamy z najlepszych materiałów zapewniających odpowiednią wytrzymałość konstrukcji.

Bardzo ważna jest dla nas ekologia. Wykonywane kotły pobierają paliwo ekologiczne, a sam proces spalania charakteryzuje się niższą emisją pyłu i substancji szkodliwych. Wszystkie kotły przemysłowe posiadają atest Instytutu Techniki Grzewczej i Sanitarnej w Radomiu oraz certyfikat wydany przez Laboratorium Badawcze Kotłów i Urządzeń Grzewczych. Nasze kotły zdobyły 5 klasę efektywności energetycznej. Produkowane przez nas wyroby są oznaczane symbolem CE/WE, dlatego mogą pracować w obiektach użyteczności publicznej: szpitalach, szkołach i osiedlach mieszkaniowych.